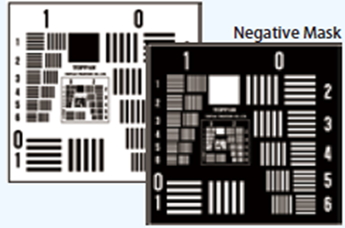

■ Major disadvantage of proximity and contact printing masks are contamination after several times exposures which results resolution degraded ad yield low. Anti-scratch or anti-finger coating not only resolve this issue but also improve printed resolution to 5um because of direct contact.

■ Another issue of direct printing is the electro-static charges built up after many times contact movement. This electrostatic charges could be prevented by AS/AF coating as well because mask Cr-film patterns are protected from direct bombardment.

AS/AF mask coating

ESD/AS mask coating

Applications:

■ Cr-mask usually suffers ESD(electro-static discharge) issue after long time friction between mask and exposed substrate. This ESD can be released by using conductive AS/AF coating offered by Cti unique technology.

■ Fluorinated SiOx ESD material materials was coated on mask using slit or spin coating that will successfully dissipate ESD to <800V and safe mask from Cr-pattern broken.

■ Specifications: ESD <800V after 100times attach and release from substrates.

■ Process: mask cleaning, then spin or slit coating Fluorinated resin on mask, finally oven baking to secure its reliability. Defect control: >5um of particle and with AOI scanning capability of 5um.

| Copy mask and Black matrix blank Black Matrix blank and Mask ■ applications: this product can replace current emulsion mask blank and also low cost film emulsion. ■ comparisons between Emulsion an black matrix blanks • Specification: black Carbon film 1.5um, OD=3.8, similar as Cr-film blank. • Resolution can be 10um which is better or similar as Emulsion blank. • Advantages of black matrix blank: better uniformity, higher sensitivity, better adhesion, larger process window • Reliabilities: high thermal resistance, higher light endurance on light and chemicals, long shelf life. ■ Benefits other than quality • it is environmental friendly material far better than Emulsion having silver halide. • Silver halide emulsion material is out of date actually, blank matrix is a material used on LCD panel and can be patterned as lithographic process. |

|

Applications:

■ mask using contact and proximity printing, with this overcoat film masks are greatly reduced particle contamination in hard and vacuum contact, which resulting mask lifetime increase..

■ PCB emulsion mask, where feature sizes are 10 to 40um, AS_mask will improve yield, because mask and substrate do not risk contact. However, where gaps are sometimes reduced to 30 microns in order to pattern 10um features, AS_mask is expected to help maintain the high process yield of small gaps.

■ Process: mask cleaning, then spin or slit coating Fluorinated resin on mask, finally oven baking to secure its reliability. Defect control: >5um of particle and with AOI scanning capability of 5um.