With over a decade experience producing blanks, glass works capability is the key to have the best competitiveness of mask blanks. From bubble screening of sodalime glass, thickness slimming, glass cutting and edge grinding, to super flat polishing.

Al these works contribute the best quality, delivery, cost and service. In summary, we can do:

- micron meter level bubble screening.

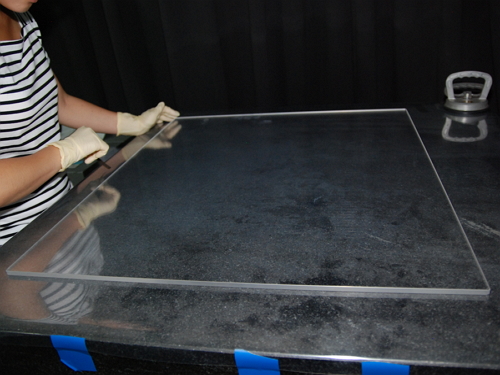

- glass cutting an edge grinding: we have CNC, laser and sandblast cutting techniques for various shapes of edge finishes, such as NC an LC, clear or fog(dark).

- thickness slimming: both chemically and physically reducing thickness and lapping.

- surface polishing: final polishing to Ra 0.10nm and TTV 2um

Cutting/slimming/polishing

Product:

Synthesis quartz, sodalime glass,boronfloat33, B270, TFT glass etc.. Maximum size: 800x960, and thickness <=10mm.

Service scopes:

- No bubble glass selection

- physical and chemical slimming of various glasses

- edge works: normal chamfer and large chamfer, clear and rough ground finishes.

- R and C-corners

- Fine polishing

- ultra flat polishing: <2um TTV

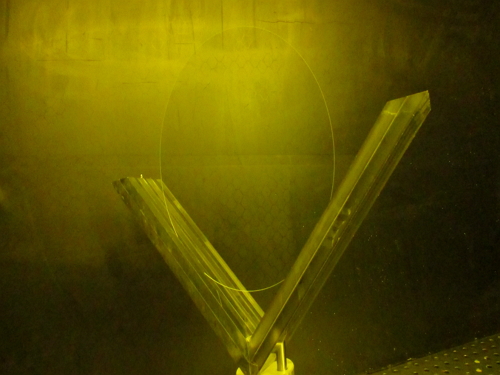

Wafer glass and Optical glass

Product: Synthesis quartz, fused quartz, sodalime glass,boronfloat33, B270, TFT glass etc.. Maximum size: 300 in diameter, and thickness <=1.8mm.

Service scopes:

- Flatness selection and control

- physical and chemical slimming of various glasses

- Class 1 cleaning (defect as mask grade)

- Fine polishing and ultra flat polishing(TTV): <3um

- Surface roughness: Ra <0.5nm and long range flatness: l/16

各式磨邊NC/LC

各式磨邊NC/LC

量測平坦度

Wafer glass

.jpg)

Wafer glass