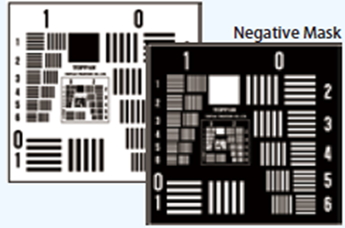

■ 進接式或是接觸式曝光的缺點是在使用後在光罩上會產生光罩汙染,致使良率降低與曝光解析度便壞。AS/AF光罩保護鍍膜可以解決此問題。AS/AF鍍膜不僅可增長使用壽命同時可使解析度增加至5um。

■ 鉻膜光罩在接觸式長時間使用後,摩擦造成的靜電常致使鉻膜電擊爆裂。因此抗靜電AS/AF鍍膜是不僅可解決靜電問題也可以增強耐刮使用問題。

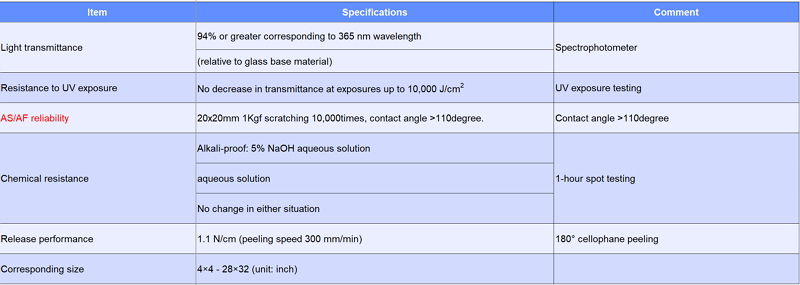

AS/AF光罩鍍膜(AS/AF mask coating)

ESD/AS 光罩鍍膜(ESD/AS mask coating)

Applications:

■ Cr-mask usually suffers ESD(electro-static discharge) issue after long time friction between mask and exposed substrate. This ESD can be released by using conductive AS/AF coating offered by Cti unique technology.

■ Fluorinated SiOx ESD material materials was coated on mask using slit or spin coating that will successfully dissipate ESD to <800V and safe mask from Cr-pattern broken.

■ Specifications: ESD <800V after 100times attach and release from substrates.

■ Process: mask cleaning, then spin or slit coating Fluorinated resin on mask, finally oven baking to secure its reliability. Defect control: >5um of particle and with AOI scanning capability of 5um.

| 複製光罩及黑色光阻光罩 玻璃Black 光阻基板及光罩 ■ 應用領域: 取代現有玻璃乳膠光罩(emulsion mask),以及低成本的film 乳膠光罩。 ■ 比較光罩底片及使用品質: • Specification: black Carbon film 1.5um, OD=3.8 與鉻膜一樣 • 製程解析力可達10um, 較現況日本乳膠優 • 冠橙碳黑材料製程特性: 高塗佈均勻性、高感度、高附著、較大顯影製程窗口 • 可靠度: 高耐熱性、高耐光性、高耐化性、高儲存安定性。 ■ 使用Cti碳黑底片效益(除品質外) • 是綠色環保物質,遠比鹵化銀重金屬佳 • 鹵化銀底片已過時材料,使用碳黑可以較易使用。 |

|

Applications:

■ mask using contact and proximity printing, with this overcoat film masks are greatly reduced particle contamination in hard and vacuum contact, which resulting mask lifetime increase..

■ PCB emulsion mask, where feature sizes are 10 to 40um, AS_mask will improve yield, because mask and substrate do not risk contact. However, where gaps are sometimes reduced to 30 microns in order to pattern 10um features, AS_mask is expected to help maintain the high process yield of small gaps.

■ Process: mask cleaning, then spin or slit coating Fluorinated resin on mask, finally oven baking to secure its reliability. Defect control: >5um of particle and with AOI scanning capability of 5um.