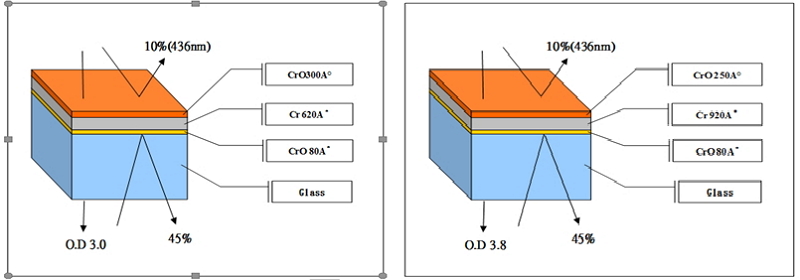

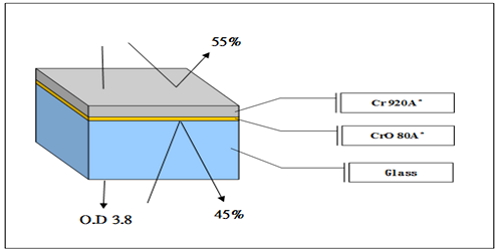

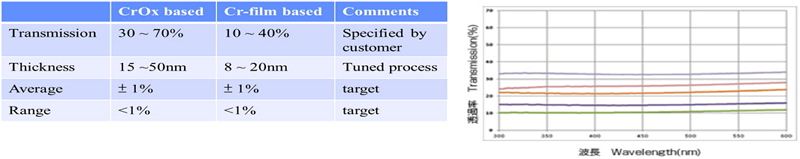

使用鍍面朝下的反應式DC 濺鍍系統,配合無油真空系統及超音波清潔前處理,可以做到無針孔的鉻鍍基板。除了標準低反射耐刮鉻膜(10%)外,可以提供封裝用高遮光(2L-film)、CMOS 攝像感測器(CIS)可見光低反射膜(C-film)、高反射(H-film)、半穿透(T-film)、可見光可視穿鉻膜(V-film)。為了曝光高精密尺寸精準度需求,鉻膜側向蝕刻率可調整至最好需求。鉻膜均勻在800x960mm範圍內光學密度(optical density; OD) +/-0.1(3%)。

| 膜種 | L | S | A | N | 2L | C | H | T | V |

|---|---|---|---|---|---|---|---|---|---|

| 適用基板 | SL | SL | Qz | Qz | SL | SL | SL / Qz | SL / Qz | SL |

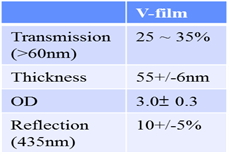

| 光學密度 | 3.8 ± 0.4 | 3.0 ± 0.3 | 3.0 ± 0.2 | 3.8 ± 0.3 | > 5.0 ± 0.5 | > 4.0 | 3.8 ± 0.4 | 1-2.0 | 3.0 ± 0.3 |

| 反射率 (λ=436nm) | 10 ± 5% | 10 ± 5% | 10 ± 3% | 10 ± 3% | 10 ± 5% | < 17% (full spectrum) | > 55% | 10+/-5% | |

| 厚度(nm) | 125 ± 12.5 | 100 ± 10 | 100 ± 10 | 125 ± 10 | 200 ± 20 | 200 ± 2 | 100 ± 10 | 20-50 ± 5 | 550 ± 55 |

| 針孔(um) | 10um | 5um | 1um | 2um | 5um | 5um | 5um | 2um | 10um |

低反射鉻膜

高反射鉻膜

半穿透鉻膜(T-film)

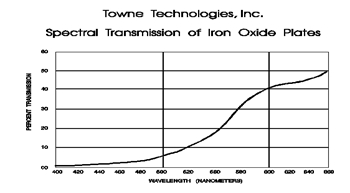

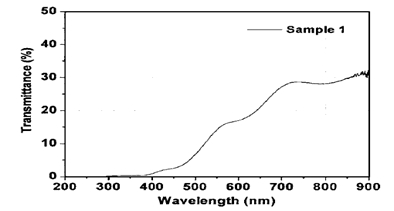

可見光可視穿鉻膜(V-film)

|

|

|

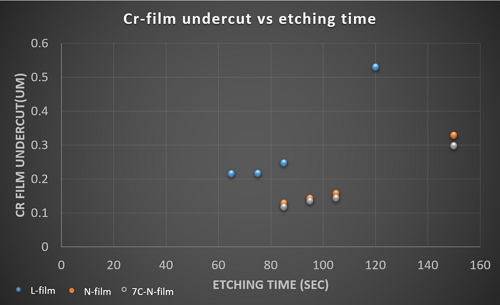

低側向蝕刻鉻膜

■ By adjusting doping concentration of Cr-film, side etching of Cr-film can be controlled within 0.15um which could allow better CD tolerance control during resist pattern etching.

■ With 100% over etching, CD still can be well controlled within <0.3um which is crucial for Soda lime mask CD control.

.jpg) |

|